Trokotex Polymer Group Sp. z o.o. to firma z tradycjami i polskim kapitałem. Oczyszczalnie ścieków, Elektrownie, Elektrociepłownie czy przemysł spożywczy od ponad 35 lat są użytkownikami wyrobów Trokotex.

Nasze produkty z kompozytu: zbiorniki, kraty, pręty zbrojeniowe czy siatki wykorzystywane są w najróżniejszych gałęziach gospodarki.

Wiele pracy, wysiłku i serca włożyliśmy przez te wszystkie lata, by stać się pewnym i stabilnym partnerem dla Państwa. Wiele starań, by sprostać dynamicznie rozwijającej się gospodarce rynkowej i wiele.

Czytaj więcej

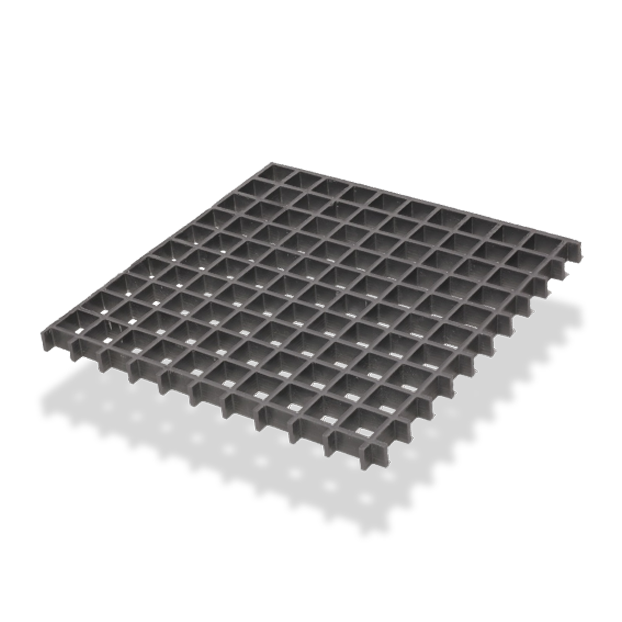

Podczas budowy różnego rodzaju kładek należy wziąć pod uwagę wiele czynników, wśród których znajduje się przede wszystkim wytrzymałość oraz ciężar poszczególnych segmentów. Firmy budowlane szukają rozwiązań, aby zwiększyć odporność na naprężenia i obciążenia przy jednoczesnym ograniczeniu wagi poszczególnych elementów.

Wychodząc naprzeciw ich oczekiwaniom proponujemy innowacyjne konstrukcje, jakimi są kraty pomostowe z tworzywa sztucznego, wzbogaconych o włókno szklane TWS. Wyróżniają się niezwykłą wytrzymałością na uszkodzenia mechaniczne – ścieranie czy pękanie, jak również niekorzystne warunki zewnętrzne – wilgoć, skrajne temperatury i nadmierne promieniowanie słoneczne.

Czytaj więcej

Jesteśmy producentem zbiorników wykorzystywanych w wielu gałęziach przemysłu, przystosowanych do kontaktu z różnego rodzaju substancjami, zarówno agresywnymi, jak i nieagresywnymi. Budujemy konstrukcje, które mogą być wykorzystywane do przechowywania substancji sypkich, gazowych oraz cieczy. Każdy z oferowanych produktów jest wykonywany na specjalne zamówienie, dlatego może być dostosowany do konkretnych potrzeb inwestora.

W naszym zakładzie wykonujemy zbiorniki o różnych rozmiarach i kształtach. Są wśród nich Kolumny kondycjonujące z TWS, Reaktory STO oraz Reaktory SBR.

Służymy fachowym doradztwem oraz pomocą przy rozwiązaniu problemów logistycznych.

Czytaj więcej

Kraty

Niezawodne kraty pomostowe (GFK / GRP / TWS). Kraty z tworzywa są nierdzewne, kwasoodporne, antypoślizgowe wykonane z wysokiej jakości włókna szklanego i żywicy.

Pręty

Pręty kompozytowe posiadają wytrzymałość na zerwanie dwukrotnie wyższą od tego wskaźnika dla zbrojenia stalowego klasy A-III przy równej średnicy.

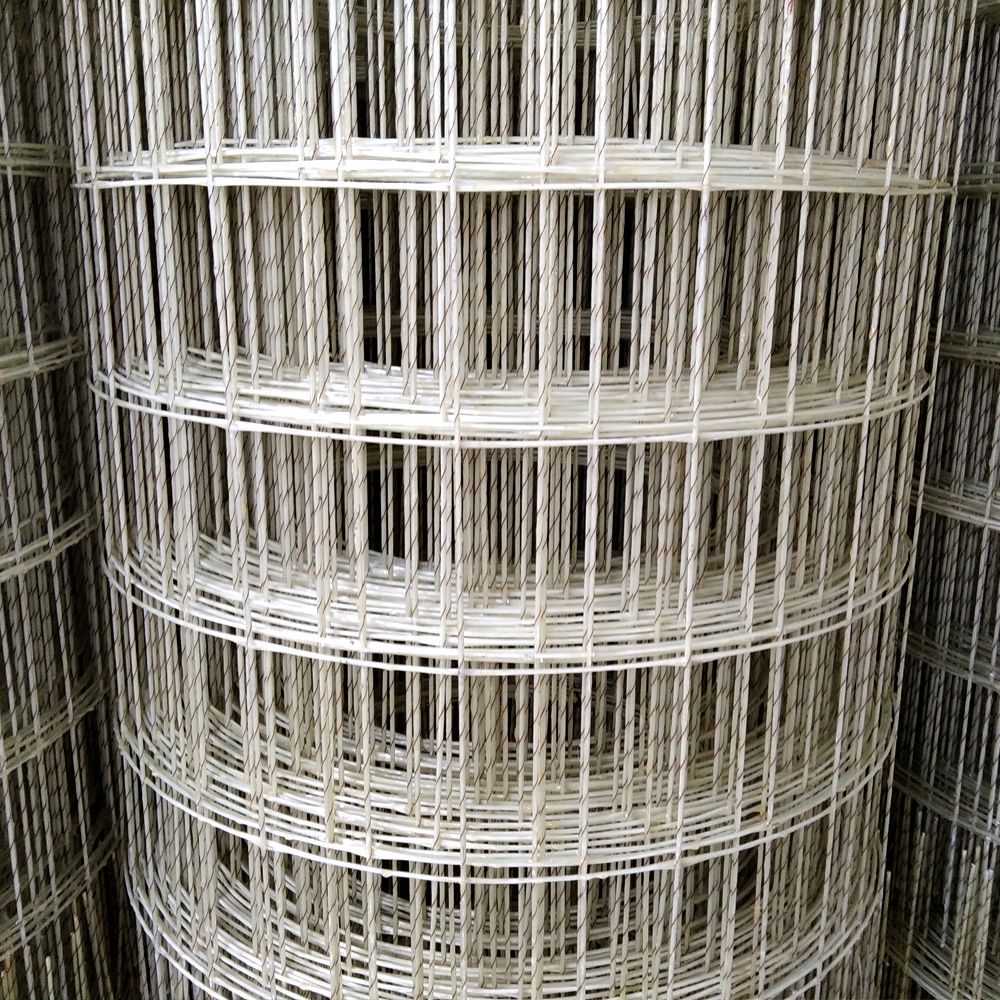

Siatki

Siatki zbrojeniowe z kompozytu TROKOTEX, przeznaczone do stosowania w konstrukcjach betonowych zamiast tradycyjnego zbrojenia stalowego.

Zbiorniki

Wszystkie nasze zbiorniki poddawane są szczegółowym badaniom w Laboratorium Badawczym, posiadającym uznanie Urzędu Dozoru Technicznego.